As the world's attention to energy efficiency continues to rise, electromagnetic equipment manufacturers are actively exploring ways to break through performance bottlenecks through collaborative innovation in materials and design. A study shows that NdFeB permanent magnets with specially designed shapes can significantly improve the energy conversion efficiency of customized electromagnetic devices, reducing energy consumption by up to 15%-30%. This discovery provides key technical support for innovations in industrial motors, medical imaging equipment and new energy fields.

Performance advantages and design challenges of NdFeB magnets

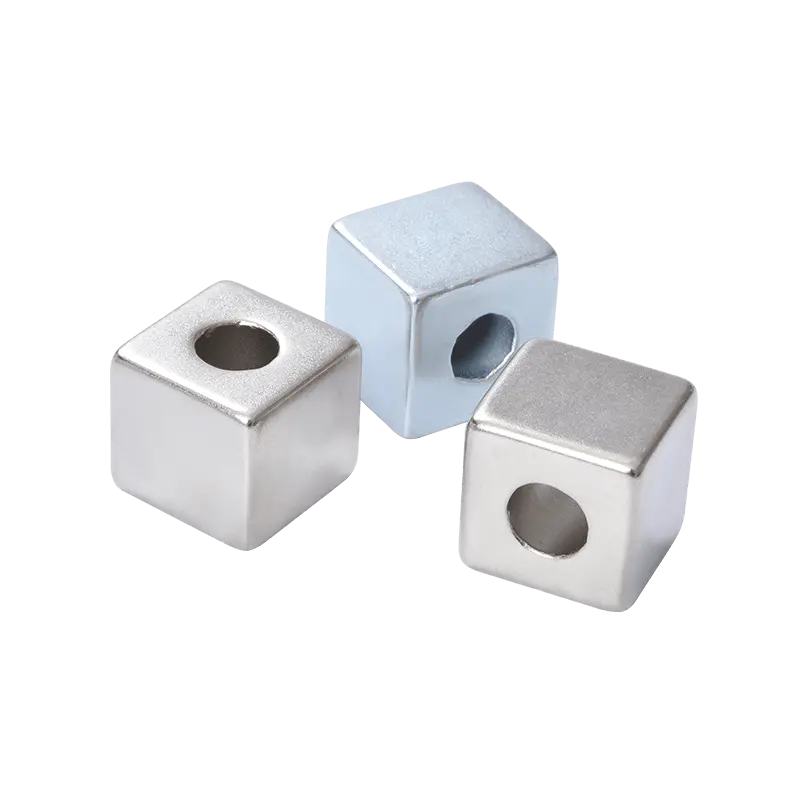

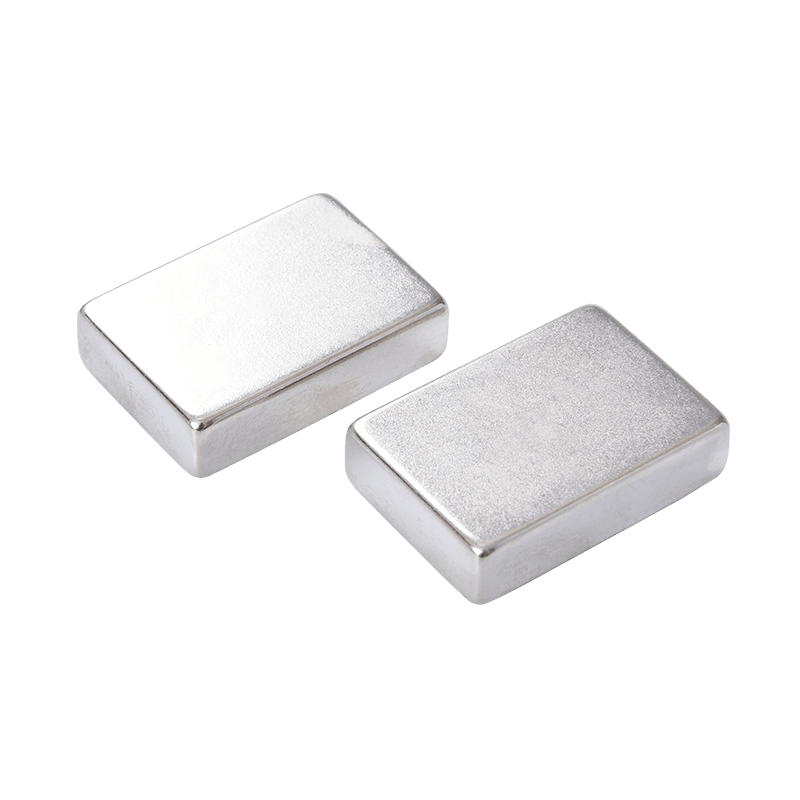

As a third-generation rare earth permanent magnet material, NdFeB has long occupied a core position in high-performance magnetic materials due to its ultra-high magnetic energy product (35-52 MGOe) and coercivity. However, the application of traditional block or sheet NdFeB magnets in complex electromagnetic devices has significant limitations:

Uneven magnetic field distribution: standard-shaped magnets are difficult to adapt to asymmetric electromagnetic structures, resulting in increased magnetic leakage;

Eddy current loss: Under high-frequency conditions, conventional geometric shapes are prone to eddy currents, reducing system efficiency;

Limited thermal stability: In high-temperature environments, magnetic performance attenuation is aggravated, affecting equipment reliability.

Special-shaped design: from topology optimization to energy efficiency leap

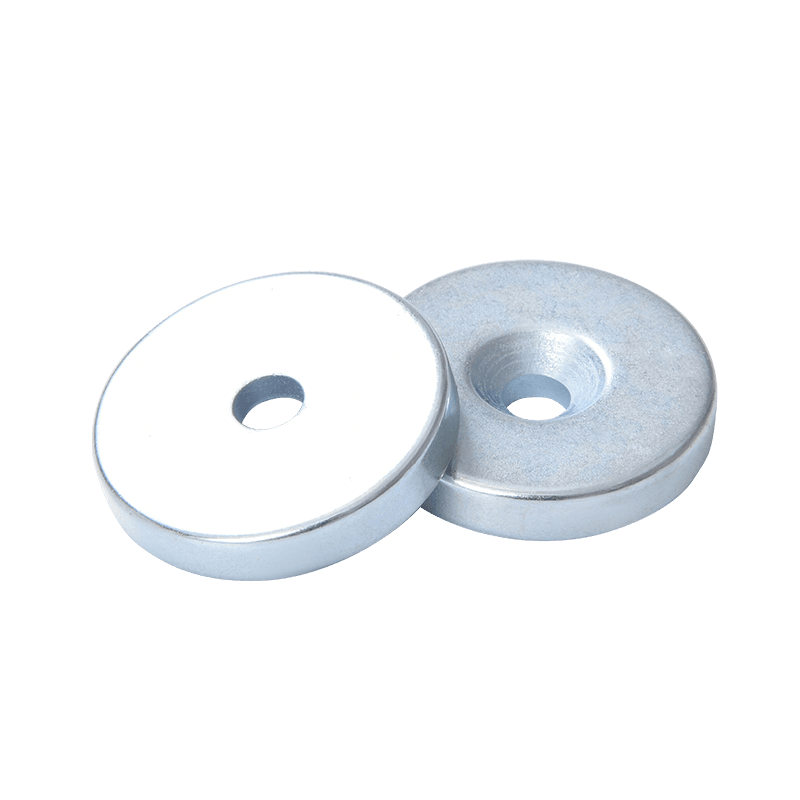

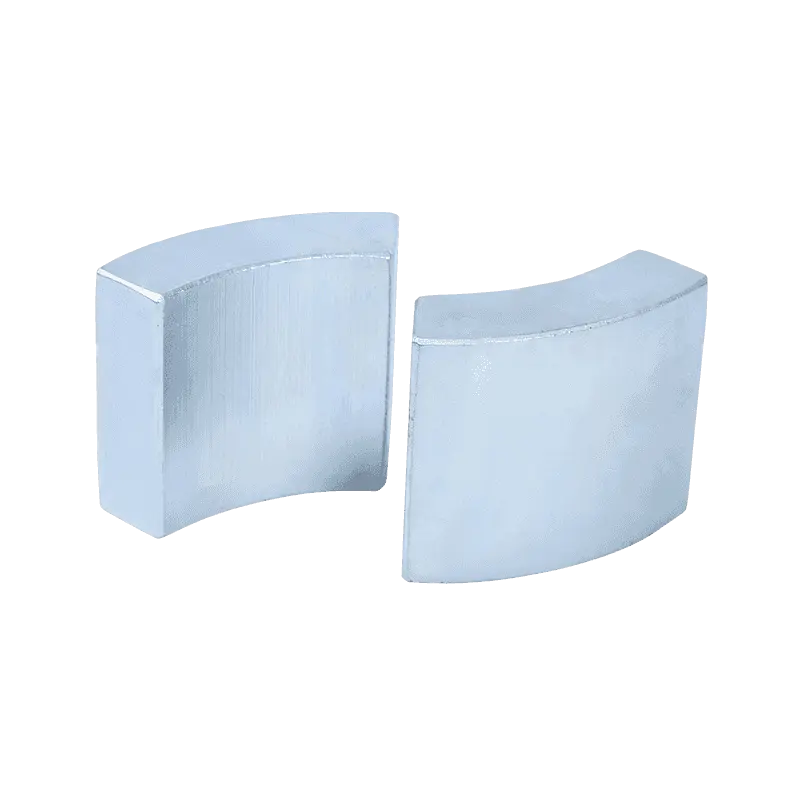

The research team has developed special-shaped NdFeB magnets for specific electromagnetic scenarios through multi-physics simulation modeling and additive manufacturing technology. For example:

Gradient thickness ring magnets: used in electric vehicle drive motors, by optimizing the radial magnetic flux density distribution, reducing iron loss by 9% and torque fluctuation by 22%;

Multipolar curved magnetic arrays: used in superconducting magnets of MRI equipment, improving magnetic field uniformity to 99.8%, while reducing liquid helium cooling energy consumption;

Honeycomb structure mosaic magnets: achieve a balance between lightweight (weight reduction of 18%) and anti-demagnetization ability in wind turbines, and the flux attenuation rate is <2% under extreme temperatures.

Experimental data show that the special-shaped design can increase the utilization rate of magnets from 65%-75% of the traditional solution to more than 90%, directly reducing the waste of rare earth materials and conforming to the trend of sustainable manufacturing.

Commercialization case: Energy efficiency revolution of industrial motors

ABB, a world-leading motor manufacturer, recently disclosed that its new generation of IE5+ ultra-high-efficiency motors using 3D printed special-shaped NdFeB magnets are 20% smaller in volume at the same power and have a comprehensive energy efficiency of 98.2%. The design effectively suppresses the cogging torque through the chamfering of the magnetic pole edge and the segmented tilting pole technology, reducing the energy consumption of the motor by 27% under partial load conditions.

Future Outlook: Deep Integration of Materials Science and Intelligent Manufacturing

With the advancement of topology optimization algorithms and powder metallurgy processes, the design freedom of special-shaped NdFeB magnets will continue to expand.

At the same time, the maturity of the anti-corrosion coating technology (such as Al-Ni composite coating) and the heavy rare earth reduction process (grain boundary diffusion method) of NdFeB magnets will further broaden its application scenarios in high temperature and high humidity environments.

English

English русский

русский Español

Español